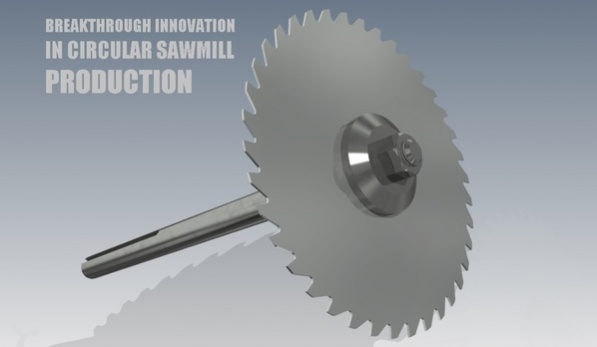

So whats the big deal with Accramax™?

Revolutionary Concept!

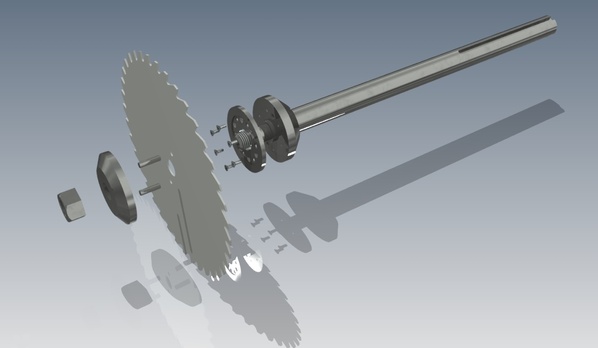

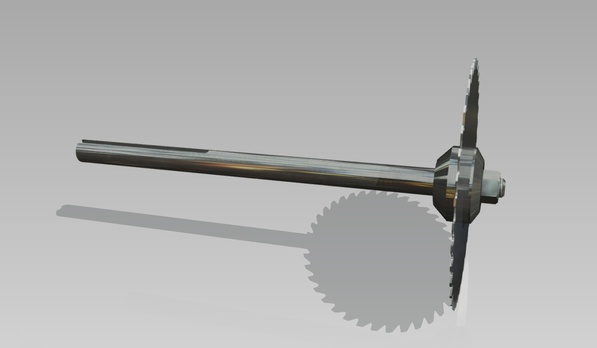

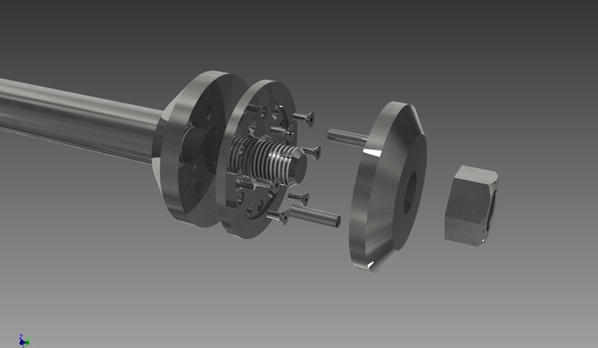

Until now, options for re-machining the contact surface of standard mandrels have required either in-place machining with a mobile rig or the removal of the entire mandrel/shaft assembly for transfer to a machine shop. Both of these options are cumbersome, expensive and can involve multi-day downtime. The innovative AccraMax mandrel features removable wear plates that can be changed out in 15 minutes or less, virtually eliminating downtime. The plates are then sent to be resurfaced.

Revolutionary Accuracy!

Because of the enormous task of resurfacing standard mandrels, proper machining tolerances are often overcorrected in a bid for more time between resurfacing incidents. Our plates are precision-machined for an ideal fit to the blade, resulting in much greater blade cut accuracy, longer blade life and faster feeding speeds. (One customer was able to put a blade he could no longer run with his OEM mandrel back into production with the AccraMax.) This allows mandrel plates to be changed more often for high product consistency, rather than being used until quality is intolerable.

A Revolutionary Production Backup Plan!

Surprises no longer need to destroy your production. An extra set of plates in inventory will essentially eliminate downtime in many cases, even in the event of an unfortunate sawmill 'wreck.'

Interested in becoming a dealer?

There is a groundfloor opportunity to become a reseller of AccraMax™ Mandrels. Give us a call to see if you qualify to join our dealer network.

Questions and Ordering

If you are ready to order or have questions, click here to send us an email. Include a good time to reach you and a brief description of the information you are seeking. Your inquiry will be directed to a properly qualified team member who will give you a call shortly. Or to reach an AccraMax representative directly, call 260-568-2534.

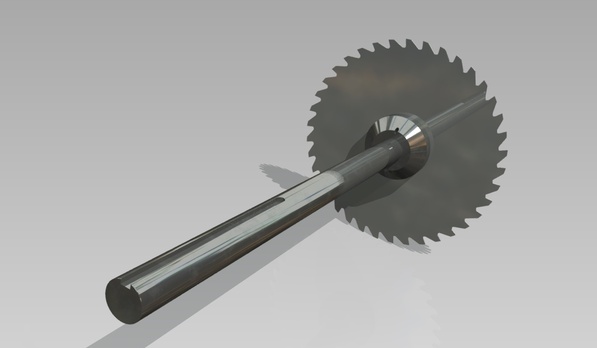

Watch a saw powered by the AccraMax Mandrel:

.png&w=180&f=png&q=95)